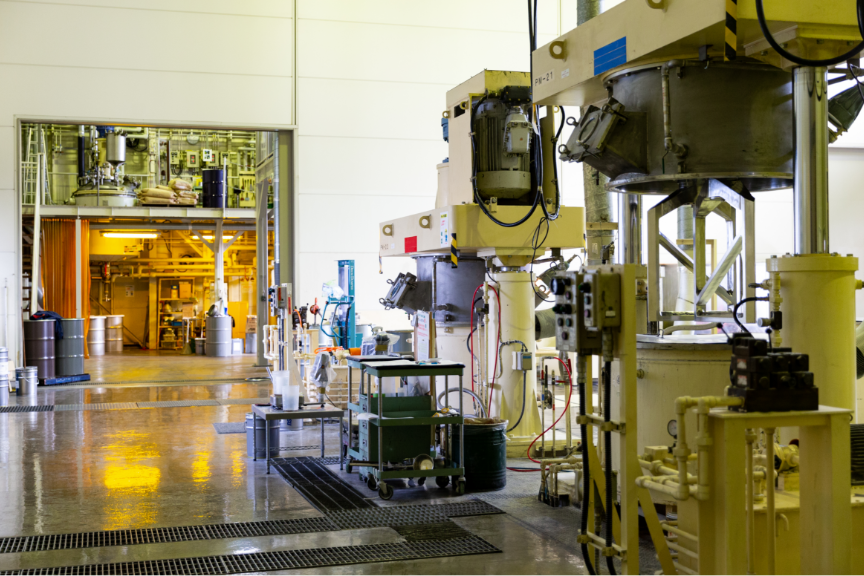

Our three plants housea variety of mechanical equipment. We can meet your manufacturing criteria, schedule, and any other needs you have.

We support a variety of resin-specific manufacturing criteria.

Sanyu Gikou has an excellent balance of the four factors of manufacturing (man, machine, material, method), allowing us to maintain both high productivity and high quality. Our three plants are installed with equipment designed for a variety of special manufacturing criteria, and we are prepared to provide support on request for products involving resin-specific manufacturing environments with factors such as moisture or temperature. Furthermore, our production status is properly managed by a system. We are prepared to take appropriate measures in the unlikely event of defects or problems. (ISO9001 certification obtained in 2007).

A Word from Our Production Manager

A Word from Our Production Manager

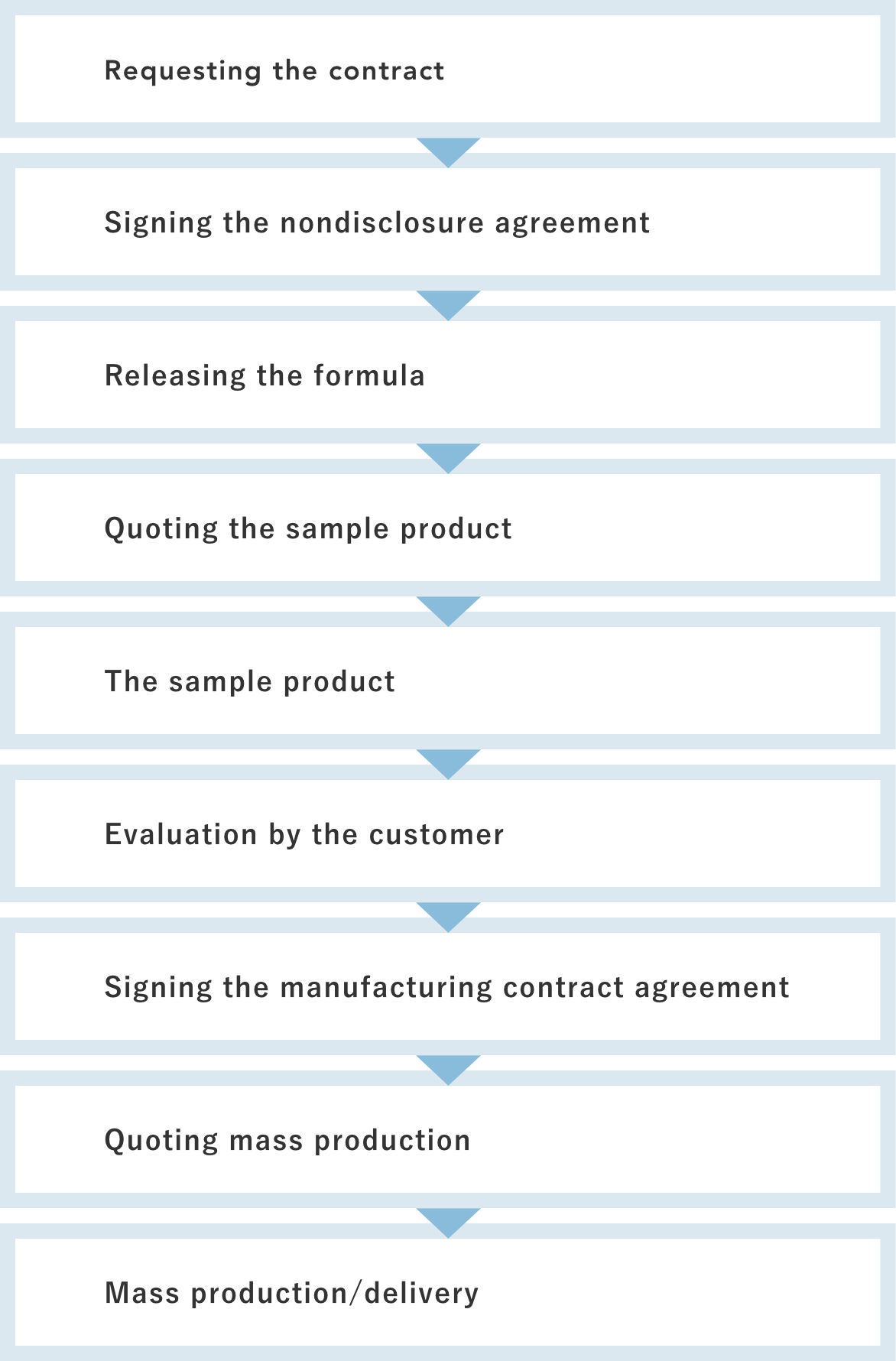

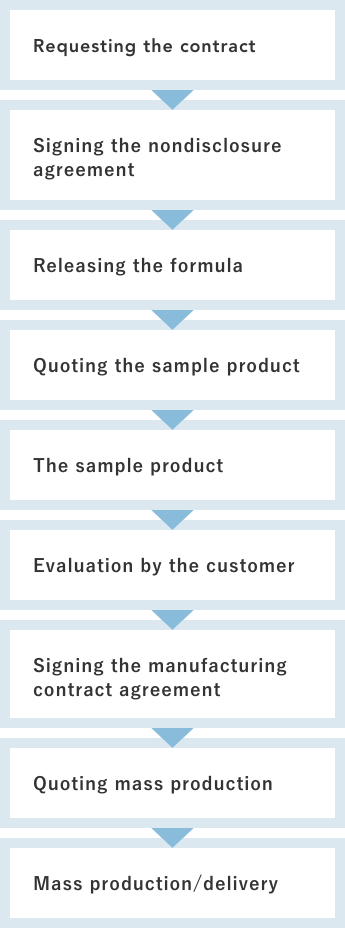

Inquiries

Inquiries